In the 21st century, sustainable development has emerged as a primary objective in industrial activities, playing a crucial role in the advancement of human society (Zimmerman et al., 2020, Chen et al., 2022b, He et al., 2022). Crude oil, an increasingly scarce and expensive resource, exhibits fluctuating and rising prices. Additionally, it significantly contributes to environmental pollution, global warming, and climate change (Meys et al., 2021, Altman, 2021). Consequently, scientists are compelled to explore renewable natural resources as substitutes for petroleum-based rea materials, aiming to address these concerns (Desroches et al., 2012). Utilizing biomass instead of oil as a raw material not only mitigates these issues but also facilitates carbon sequestration (Stegmann et al., 2022). Among renewable natural resources, vegetable oil holds significant importance in the production of polymer materials (John et al., 2019). The vegetable oils, including soybean oil, castor oil, sunflower oil, palm oil, rapeseed oil, olive oil, linseed oil, canola oil, among others, exhibit a global annual production of approximately 251 million tons in 2020 (Rajpoot et al., 2022). These oils find applications primarily in human food (76%), technical uses (19.5%), such as soap and oleochemical industry, and other applications (1.5%) (Alagi and Hong, 2015, Zlatanić et al., 2004). Plant extract oils offer abundant, cost-effective, and sustainable alternatives, possessing inherent chemical functional groups that promote greener chemistry practices (Islam et al., 2014). Among vegetable oils, castor oil stands out as an excellent alternative due to its hydroxyl group, low toxicity, biodegradability, cost-effectiveness, industry suitability, and availability (Shaik and Alam, 2015, Zhang et al., 2020). Numerous studies have proposed castor oil as a polyol source to replace petroleum-derived products (Paraskar et al., 2021). Despite castor oil seeds accounting for only 3 % of worldwide plant oil seeds (Rajpoot et al., 2022), non-edible castor oil can be easily extracted from castor plants that thrive even in arid regions (Chakraborty and Chatterjee, 2020). Moreover, the versatile properties and expanding applications of castor oil, coupled with the growing interest in biopolymers and biofuel industries, have significantly enhanced its potential role in the global economy in recent years (Zhang et al., 2020). Notably, castor oil prices have demonstrated a consistent upward trend, rising from $ 946 per ton in 2002–2003 to $ 2390 in 2010–2011 (Pavaskar and Kshirsagar, 2013). The economic contribution of castor oil is projected to continue increasing, with estimates suggesting that the global market of the global castor oil and derivatives was evaluated as 2.3 billion USD in 2018. (Singh et al., 2023).

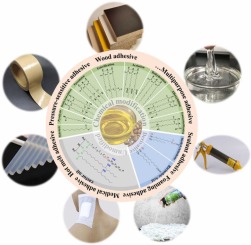

Adhesive bonding is a widely utilized assembly component technology (Ramalho et al., 2022), employed across various industries, including wood processing (Huang et al., 2022), medicine (Zheng et al., 2022), textile (Tian et al., 2022), and electronics (Yan et al., 2023), and so on (Tian et al., 2022, Droesbeke et al., 2021, Bao et al., 2020). In 2019, the global adhesives market reached a production capacity of 14.7 million tons, with the Asia Pacific region accounting for nearly 38 % of the global share, followed by North America and Western Europe (Gonçalves et al., 2021). Currently, the majority of adhesives are synthesized from petroleum-based raw materials such as urea-formaldehyde resin, epoxy resin, polyurethane. However, these adhesives release harmful substances like formaldehyde during production and use, posing significant environmental and safety concerns (Gao et al., 2021, Łebkowska et al., 2017). Furthermore, the depletion of resources is expected to lead to a severe shortage of petrochemical products. Therefore, there is a need to replace petroleum-derived ingredients in adhesive formulations. Interestingly, the concept of bio-based adhesive is not new, with historical evidence of their use dating back to ancient times when natural macromolecules from plants or animals were utilized for glue production. In the early 20th century, natural adhesives such as starch and casein proteins, were employed. However, their use was limited due to their low durability and poor water resistance. Developing high-performance bio-based adhesives that surpass their petroleum-derived counterparts remains a challenging endeavor (Heinrich, 2019, Román and Wilker, 2018, Chen et al., 2020). To address these issues, efforts have been made to develop new polymer adhesives using renewable resources (Wu et al., 2021). Among these resources, vegetable oil holds significant potential for replacing components in petroleum-based adhesives. Vegetable oils offer not only monomers, fine chemicals, and polymers (Maassen et al., 2016), but also serve as the fluid medium for polymerization processes that lead to adhesive polymer networks. Additionally, compared to other renewable resources, vegetable oil boasts a simple composition, clear molecular structure, exposed active groups, and ease of molecular design. Triglycerides, which are esters of glycerol with three long-chain fatty acids constitute the major components of vegetable oils, with their compositions varying based on the oil source (Miao et al., 2014, Xia and Larock, 2010, Galià et al., 2010). Fig. 1a illustrates the general molecular structure of triglycerides. The physical and chemical properties of vegetable oil primarily depend on the fatty acids, including the length of the fatty acid chains and the number and position of double bonds within them (Zlatanić et al., 2004).

Castor oil, depicted in Fig. 1b, possesses three hydroxyl groups and an approximate unsaturation/triglycerides ratio of 3.04, with a hydroxyl group on the 12th carbon. Notably, it is the sole commercially available vegetable oil containing hydroxy acid. As a polyol, castor oil can readily react with isocyanate to produce biodegradable polyurethane without the need for addition modification. Furthermore, the double bond present in castor oil allows for epoxidation, and the ester group serves as an active site for potential chemical modifications and biodegradability. Consequently, castor oil presents itself as a promising candidate for use as a cross-linking monomer in polymer synthesis (Garrison et al., 2014, Liang et al., 2019). These characteristics highlight the significant potential of castor oil in the development and application of bio-based biodegradable adhesives.

This paper provides a brief overview of the properties of castor oil and explores various chemical modification reactions, such as addition, transesterification, epoxidation, and esterification. The primary focus is on the application of castor oil and its derivatives in adhesives, specifically discussing their preparation processes and the roles they play in adhesive formulations.