Esters of fatty acids and alcohols have several real life applications, which include their use in lubricants, greases, plasticizers, resins and many others (Fu et al., 2019, Monteiro et al., 2024). Emerging interest in ‘going green’ promotes the use of fatty acid-based materials because of their low migration and toxicity in addition to better biodegradability (Jiang et al., 2024, Kalousková et al., 2024). Castor oil and its derivatives have enormous potentials as “speciality chemicals”. The attributes of speciality chemical is majorly contributed by high percentage of ricinoleic acid, formally known as 12-hydroxyl-9-cis-octadecenoic acid, present in castor oil. Ricinoleic acid is a uniquely hydroxylated, monounsaturated aliphatic acid with a terminal carboxyl group and a pendant hydroxyl group (Fu et al., 2019, Monteiro et al., 2024, Jiang et al., 2024, Mukherjee and Ghosh, 2020, Preetam et al., 2023). Castor oil based plasticizers generally offer better performance over phthalates or other plasticizers mainly because of ricinoleic acid. It is odorless and completely biodegradable (Ma et al., 2021). Additionally, it has been reported that bio-plasticizers derived from castor oil also yield the desired softness and flexibility. Furfural, on the other hand is a pentosan-rich lignocellulosic biomass-derived organic compound, which on hydrogenation transforms into furfuryl alcohol (FA). FA readily polymerizes under acidic conditions and forms a thermo-stable polymer that is widely applied in foundry industry as bio-renewable plasticizer. Most of the plasticizers are usually synthesized via esterification reactions between corresponding acids/anhydrides and alcohols in the presence of acidic catalysts (An and Li, 2022, Gómez Millán and Sixta, 2020, Jorqueira et al., 2023).

Nevertheless, the use of bio-catalyst in oleochemical industry is gaining impetus over the traditional chemical processes due to their low energy budget and high purity. Nowadays, introduction of lipase catalysts opens a new frontier in esterification processes, which has a huge potential in industrial applications (Bell et al., 2021, Winkler et al., 2021, Yi et al., 2021). There exists plethora of characterization as well as kinetic studies related to biocatalytic esterification processes. A kinetic study was reported (Chowdhury et al., 2016) regarding the Novozyme 435 catalyzed esterification of free fatty acids from waste cooking oil with octanol to produce octyl esters and the study showed that the entire reaction followed the Ping-pong bi-bi kinetics without any inhibition by substrates or products within their studied concentration range. Lorenzo analyzed the kinetic model on the enzymnatic synthesis of pentyl acetate using Novozyme 435 (Lorenzo et al., 2023, Zaidi et al., 2002). Bansode investigated the kinetics and optimization of lipase catalyzed esterification reaction of isoamyl propionate in solvent-free systems (Bansode and Rathod, 2022). Lopresto et al. have also reported a research on the kinetic analysis of Candida antarctica lipase B catalyzed esterification of octanoic acid and hexanol. The study showed a pattern of bi-substrate inhibition which followed Ping-Pong bi-bi mechanism with dead-end inhibition by both substrates and, based on the experimental model, the kinetic constants of the esterification reaction were estimated. The study also investigated the ester inhibition and catalyst denaturation by the substrates and the effect of the reverse reaction was also evaluated (Lopresto et al., 2014).Ping-Pong bi-bi model with dead end inhibition by both the substrate acid and alcohol was also reported by Waghmare et al.while studying the esterification of butyric acid and cinnamyl alcohol using immobilized Novozyme 435 lipase (Waghmare et al., 2017). Same kind of inhibition was observed by both Hazarika et al. for the synthesis of ethyl oleate using Porcine pancreatic lipase in various organic solvents (Hazarika et al., 2002).Similar pattern of inhibition was also observed in the kinetic study of aroma pyridine esters synthesis catalyzed by Novozym 435 (Zhao et al., 2023). Bhavsar investigated the kinetics of esterification of levulinic acid with n-butanol by using immobilized Novozyme 435 lipase in tert butyl methyl ether medium. They also reported the reaction followed Ping -Pong bi-bi model with dead end inhibition by both the substrates (Bhavsar and Yadav, 2018). Similarly Cordier and team investigated the kinetic model for the production of n-butyl levulinate, where kinetic models were developed and evaluated for the synthesis of n-butyl levulinate over commercial Novozyme 435 using microfluidic technology, across various temperatures (Cordier et al., 2023).

Yadav and Devi reported a kinetic study on hydrolysis of tetrahydrofurfuryl butyrate using immobilized Candida antarctica lipase (Yadav and Devi, 2004). Based on initial rates and concentration profiles of the ester, the hydrolysis reaction was found to follow the ping-pong bi-bi mechanism with inhibition by water as reactant. Zaidi et al. have investigated a study on the esterification of long-chain fatty acids and n-hexane which was catalyzed by nylon-immobilized lipase from Candida rugosa where Ping-Pong bi-bi mechanism with bi-substrate inhibition was found to be observed in the kinetic behavior of all esterification reaction (Zaidi et al., 2002). Gofferjé et al.reported the kinetics of esterification of enzymatic esterification of glycerol and free fatty acids in crude Jatropha oil by immobilized lipase from Rhizomucor miehei, where esterification reaction also followed the Ping -pong bi bi model with competitive inhibition by glycerol (Gofferjé et al., 2014). Sengupta et al. have synthesized ester of furfuryl alcohol and oleic acid using immobilized Candida antarctica lipase B and the esterification reaction also followed the Ping-pong bi bi model of enzyme inhibition (Sengupta et al., 2012). D-isoascorbyl palmitate was also synthesized via lipase catalyzed esterification reaction (Bell et al., 2021, Sun et al., 2013, Samal and Preetam, 2022, Bhattacharya et al., 2023). Zulkeflee et al. reported the kinetic modeling the esterification process catalyzed by immobilized Candida rugosa lipase in a batch reactor, which is equipped with a control system for temperature and water activity (Zulkeflee et al., 2020).

On the other hand, Shintre et al. have described ping pong bi bi model without substrate and product inhibition for the esterification of lauric acid with cetyl alcohol using immobilized lipase (Shintre et al., 2002). Arcos et al. have also reported the kinetics of esterification reaction without substrate and product inhibition. The study showed lipase-catalyzed esterification of fatty acids and glucose in acetone (Arcos et al., 2001, Qi et al., 2024).

Though comprehensive studies on bio catalysis show use of organic media, there arise many constraints for commercial set-up of such processes. Use of huge quantities of organic solvents may cause enzyme inactivation and also the recovery process is very expensive along with high energy consumption. In addition, the disposal of such solvents poses environmental threat. Hence the solvent-free reactions can be an eco-friendly and cost-effective options in comparison to reactions in organic media (Bell et al., 2021, Winkler et al., 2021, Yi et al., 2021, Wang et al., 2021). There are few works which have been reported on enzymatic esterification in solvent free medium. A study of solvent-free enzymatic esterification reaction of methanol and lauric acid in eutectic substrate reaction mixture was reported by Pätzold et al. where the product formation rate was well fitted with the predicted model (Bell et al., 2021, Pätzold et al., 2019). Zhong et al. have also reported lipase catalyzed synthesis of alkyl oleates in solvent-free systems (Zhong et al., 2013, Monteiro et al., 2023).

Exhaustive literature review indicates that all the previous all the studies have majorly based on one or more of the following nodal features: (i) Performance characterization of esterification reaction with respect to different process parameters followed by optimization study (ii) identification of most appropriate kinetic model and subsequent evaluation of kinetic parameters (iii) influence of process parameters on physio-chemical properties of ester and (iv) Influence of chemical properties of alcohol (for instance, chain length in case of aliphatic alcohols), fatty acids and enzymes in overall kinetics and equilibrium yield (Monteiro et al., 2024, Monteiro et al., 2023, Jiang et al., 2024, Bell et al., 2021, Yi et al., 2021, Wang et al., 2021). However, in relation to conjugate kinetic studies and process optimization, it is necessary to further investigate the techno-economic feasibility of applying optimal parametric condition in industrial systems. Unforeseen constraints for example, problems of limited feed stocks, safety limits of temperature, restricted enzyme loading etc.

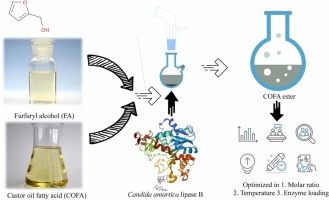

In the present study, different kinetic parameters, present in corresponding rate equation, such as the Michaelis-Menten constants, inhibition coefficients etc. Were evaluated under varied conditions of temperature, molar ratio of reactants and enzyme loading in order to decipher the nature of their dependence on experimental parameters. Respective functional forms were quantitatively evaluated using standard Response Surface Methodology (RSM). This is unambiguously a novel attribute of the present work because respective outcome might be helpful in local optimization of process conditions in cases where the global optimum is beyond the scope of existing production facility. Castor oil fatty acid (COFA) is esterified in a solvent free system with FA using immobilized Lipase B obtained from Candida antarctica (NS 435). Kinetic study was carried out using the well-known ping-pong bi bi mechanism (Lorenzo et al., 2023, Lopresto et al., 2014, Sengupta et al., 2012, Żarska et al., 2024).