Thermosetting polymers are heavily used in the engineering industry owing to their light weight, mechanical durability, stable thermal properties, and low cost. Among them, traditional thermosets with highly immobilized chemically crosslinked networks exhibit extraordinary mechanical properties and chemical tolerance; however, their irreparability, antidepolymerization, and poor reprocessability result in resource crises and environmental pollution [[1], [2], [3]]. To overcome these challenges, covalent adaptable networks (CANs) have been introduced into thermosetting materials to optimize their reshaping, self-healing, and recyclability without sacrificing mechanical properties [[4], [5], [6]]. Since the groundbreaking work of Leibler and colleagues in 2011 [7], various thermosetting materials have been developed using dissociative or associative CANs [8]. Diels–Alder cycloaddition [9], transesterification [10], transcarbomylation [11], oxime ester [12], boronic ester exchange [13], disulfide bonds [14], and dynamic imine bonds [15] have been employed to build dynamic crosslinking networks for reshapable thermosets.

However, recent efforts to achieve carbon neutrality require sustainable self-healing thermosetting materials that can be produced from renewable resources without a catalyst and are biodegradable. The production of biobased sustainable polymers based on vegetable oils [16], vanillin [17], camphoric acid [18], cardanol [19], catechol [20], eugenol [21], tung oil [22], furan [23], and isosorbide [24] has been extensively studied. Wu et al. [25] reported a full biobased vitrimer comprising soybean oil and glycyrrhizic acid. Benefiting from the ester exchange-induced CAN rearrangement, the resulting vitrimer possessed impressive welding and shape memory performance but suffered from high self-healing temperature (200 °C) and long healing time (60 min). Geng et al. [26] prepared reusable vanillin-based vitrimers with incorporated dynamic imine covalent bonds endowing the polymer networks with enhanced recyclability in a strong acid solution; however, they exhibited self-healing properties only when heated at 180 °C and fully healed after 2 h. Manarin et al. [27] synthesized novel bio-based 2,5-furandicarboxylic acid-derived epoxy vitrimers, which exhibited 100 % self-healing efficiency at 160 °C for 30 min but struggled with poor mechanical properties (<1 % strain elongation). In short, although the study of biobased thermosetting materials has been gradually intensified, challenges remain in the self-healing of biobased CANs, such as the high temperature and pressure requirements of CANs for self-healing and the sluggish self-healing rate. Thus, achieving mechanically strong, recyclable, and weldable CANs at low temperatures (<100 °C) is essential for the fabrication of biobased thermosets with self-healing characteristics.

Castor oil (CO)-derived polyurethanes (PUs), denoted CPUs, are drastically limited because they cannot be reprocessed, reshaped, or recycled and because they show low strength, poor toughness, and insufficient functionality due to their permanently cross-linked structure with a high cross-link density and a soft backbone [[28], [29], [30]]. Wang et al. [31] developed novel reversible piperazine–urea bonds (PaUBs) from inexpensive piperazines and isocyanates and incorporated the PaUBs into CPUs to fabricate sustainable and reprocessable poly (urethane urea) covalent adaptable networks (CANs).

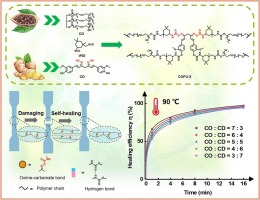

Herein, in this paper, a fully biobased CAN comprising curcumin dioxime (CD) and castor oil (CO) was constructed. By tuning the CD/CO ratio, the mechanical and thermal properties were modulated. The CANs displayed superior elongation ratio, reprocessability, and welding performance. More importantly, combined with confirmed exceptional self-healing efficiency at 90 °C, the prepared biobased CANs open a new design methodology for the production of biobased sustainable thermosets.