With the increasing demand for the automotive industry, sustainability has become a driving force in the contemporary world i.e., Industry 4.0, energy and resource conservation as well as emissions reduction have become crucial to encircle environmental concerns [1]. Although, lubricants serve as an insulator and a sealing agent in many industrial processes, as well as it plays a significant role to reduce wear and protecting from corrosion via reducing oxidation, manifested in Fig. 1 [1]. Mineral oils, synthetic oils, refined oils, and Petro-based are different varieties of lubricants that are approachable globally. To a large extent, the massive use of fossil fuel or Petro -based lubricants will upraise pollution and will emit large amounts of carbon footprint to the surrounding which ultimately results in implying array of problems from an environmental and social point of view such as disruption of the marine and terrestrial ecosystems.

The size of the worldwide lubricant market, which was estimated at USD 125.81 billion in 2020, is anticipated to increase at a CAGR of 3.7 percent from 2021 to 2028 [2]. With the expanding commerce of automobiles and their spare parts in the Indian finished lubricants industry, serves as the third-largest and one of the fastest-growing lubricants markets in the world. At the outset, the Indian finished lubricants industry, is expected to increase at a CAGR of 4.77 percent by 2027 [2].

Furthermore, beyond rectifying the current environmental degradation, there is a growing demand for green technologies that can provide clean, safe, sustainable, and high-quality energy resources for a better future. As a result, researchers are driven to explore inventive methods to integrate sustainable energy with suitable technologies for meeting the diverse product requirements of various industries [24]. Plant-based oils are likely, a very viable alternative to put back the standard fossil fuel-based i.e., mineral oils for lubricant formation because they are structurally equivalent to the long-chain hydrocarbons [19], [20], [24], [25], [37] in mineral oils. Moreover, plant-based oils [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36], [37], [38] are also renewable, non-risky, economically viable, and ecologically friendly. Lubricants are created from vegetable oils and utilized as a sustainable resource that is used in machinery and automobiles. So, it is desiderium to shift from long-established fossil fuel-based lubricants to more sustainable ones as a feasible replacement which will convey worry about their feasibility and in addition numerous environmental difficulties.

According to Statistics published by Eon Market Research as a research report entitled ‘Global Bio-lubricants Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2028′ states that, “Being renewable, non-toxic, economic and environmentally friendly, the global Bio-lubricant market size is expected to value at USD 2939.7 million in 2021 and estimated to capture the value of USD 4209.7 million by 2028 with a CAGR of 5.3% during review period [3].” In the past decade, the world has been shifting towards clean and green resources of energy because of the increasing issues over the employment of petroleum-based products that cause progressive reduction of fossil fuels and issues over the impact on the surroundings. Since conventional mineral oil-based lubricants [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36], [37], [38] impact both the marine and terrestrial ecosystems due to their poor biodegradability, vegetable oil-based bio-lubricant will able to provide a non-toxic, ecologically sound, biodegradable, sustainable alternative to the unpreceded increasing demand for lubricant in Indian markets [1].

The use of renewable resources within the business is important to confirm property development. Within the past, a number of researchers had done connected work related to the Design and developmental manufacturing process for Bio-lubricant production from a great variety of sources of both edible and non-edible vegetable oils. Therefore, this study underlines the characterization, importance, and manufacturing of vegetable oil i.e., castor plant (Ricinus communis) [23] based bio-lubricant as a sustainable substitute via Chemical softening [15], [16], [17], [18], [20], [27], [28], [29], [30], [33], [34], [36] processes. Based on the detailed study, the comparison between the array of properties and physicochemical characterization of various vegetable oils to produce bio-lubricant are listed in Table 1.

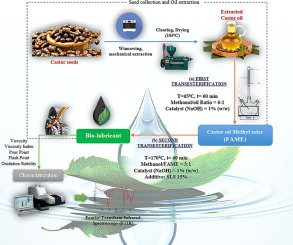

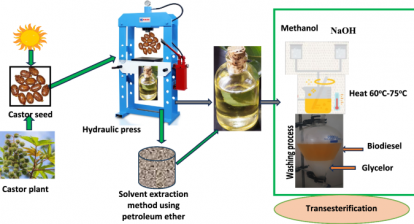

Numerous research studies contribute valuable insights to the field of sustainable lubricant development, presenting promising approaches and catalysts for creating environmentally friendly bio-lubricants from various vegetable oil [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36], [37], [38] sources. Such eco-friendly alternatives align with the growing demand for green technologies and can have significant implications for different industries seeking more sustainable solutions [35]. Comprehensive studies investigated different methods, including successive esterification and trans-esterification [4], [5], [6], [7], [8], [9], [11], [12], [13], [14], [15], [16], [17], [18], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36] processes, to produce bio-lubricants from diverse vegetable oils such as castor oil [4], [6], [14], [15], [18], [23], [24], [29], [30], [34], [37], palm oil [12], [22], [33], sunflower oil [17], [20], [27], coconut oil [15], [20], [38], soybean oil [7], [5], [19], [33], [35], [36], and others. Notably, Annisa, A.N. et al. [5] focused their work on palm oil as the primary raw material, utilizing Transesterification with Sodium methoxide as the catalyst in an oscillatory flow reactor, resulting in the formation of Palm methyl ester (PME) and Trimethylolpropane (TMP) with an impressive overall yield of approximately 94.6%. Ibrahim N. Dibal et al [4] implemented the process for the production of bio-lubricant synthesized from castor oil in two stages: esterification of the oil yielded methyl ester, which was then trans-esterified with a homogeneous catalyst (NaOH) in the successive stage. In order to obtain better yield results and high-grade bio-lubricant, obtained methyl ester was combined with 15% w/w Sodium Lauryl Sulphate (SLS) [4], and an additional secondary additive known as Cocamidopropylbetaine [4] is utilized. In addition, the results and findings were calibrated and compared to Motor Lube’s mineral-based lubricant standards (SAE 20 W-40 – reference lubricant) [4], [7], [19].

In order to reduce the environmental impact of traditional lubricants, bio-lubricants have been developed from non-edible castor beans by utilizing Potassium hydroxide (KOH) [4], [8], [14], [15], [16], [17], [18], [19], [20], [23], [24], [34] as a catalyst for transesterification resulting in the production of methyl ester using purified castor oil and methanol at room temperature via the Base catalyzed method which aimed to synthesize base oil i.e., Fatty acid methyl ester (FAME) by Biniyam T. et al [14]. Density, kinematic viscosity, acid value or free fatty acid (FFA) composition, and moisture content of the produced base oil are calibrated and compared to the standard set by the American Society for Testing and Materials (ASTM) [35] and European Standards (EN) [35] for FAME composition [8], [10], [13], [14], [5], [15], [16], [17], [25], [33]. Study led by José Mara Encinar et al.[6], delved into determining the optimizing temperature, alcohol/methyl ester molar ratio, and catalyst concentration to achieve maximum conversion efficiency for the production of bio-lubricants using methyl esters derived from vegetable oils, specifically rapeseed and castor oil methyl esters and employed titanium isopropoxide [6] as a catalyst.

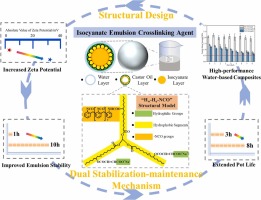

A novel sustainable lubricant inspired by natural materials, employing a structure-based approach, Trevor Romsdahl et al. [9] explored the use of plant-based oils, particularly Jojoba i.e., Ov (Orychophragmus violaceus)[9] known for their excellent lubrication properties. Instead of blending conventional and synthetic oils with additives, the produced lubricant uses Jojoba-based oil to improve the viscosity, anti-corrosion, and antifoaming features in lubricating oil formulations. The study introduced by Ebtisam K. Heikal et al. [8], focused on using commercially available palm and jatropha oils in two consecutive stages of trans-esterification, employing Potassium Hydroxide (KOH) [4], [8], [14], [15], [16], [17], [18], [19], [20], [23], [24], [34] and Sodium methoxide[4], [8], [14], [34] as catalysts, to produce bio-lubricants. In the second stage, Sodium methoxide was used as the primary catalyst to combine biodiesel with trimethylolpropane, resulting in palm or jatropha oil-based trimethylolpropane esters (bio-lubricants). Despite high pour points, the bio-lubricants demonstrated standardized lubrication properties comparable to commercial industrial oil ISO VG46 [4], [7], [8], [27]. The selection criteria for feedstocks, the esterification and transesterification processes, and chemical modifications to achieve higher yields and high-grade lubricants with overall tribological performance were characterized by Godfred Appiah et al. [10]. To produce Biodiesel and Bio-lubricant, rapeseed, a combination of corn and sunflower, and frying oils are used as the primary raw materials; José Mara Encinar et al [11] provided assistance during the manufacturing and characterization process. Initially, KOH was used as a catalyst during the transesterification of Oil/Methanol ratio 6:1 to produce biodiesel at a temperature of 65 °C followed via transesterification with a FAME/alcohol ratio of 1:3, utilizing 2-ethyl-1-hexanol as the alcohol in the presence of titanium isopropoxide (1.5%) at 170 °C [11], [14].

Castor oil has been attracting increasing attention due to its distinctive physicochemical properties, setting it apart from conventional edible and non-edible oils primarily because of its rich ricinoleic acid content. Ricinoleic acid [20], [24], [25], [34], comprising around 85 to 90% of castor oil’s fatty acid composition, possesses three functional groups. These include a carboxyl group (–COOH) responsible for its acidic nature, a hydroxyl group (–OH) at the 12th carbon, giving it unique hydroxy-fatty acid characteristics, and a carbon–carbon double bond (C = C) that makes it a mono-unsaturated fatty acid [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34]. The presence of the carboxylic group in ricinoleic acid allows for a diverse range of esterified products to be formed. Additionally, the single point of unsaturation in the carbon chain can be altered through chemical softening processes like hydrogenation [15], [16], [20], [23], [37], epoxidation [15], [20], [27], [28], [29], [30], carbonation [15], [20], [23], [37], maleation [20], acrylation [20], [23], hydroxylation [23], [37], hydroformylation [37], reduction [30], [34], thiolene addition or vulcanization [20] further expanding the potential applications and versatility of castor oil derivatives in various industries. Owuna, F.J. et al [7] in 2020, revised the production of bio-lubricants via Chemical modification of various vegetable oil and seed via consecutive transesterification processes to confirm optimum parametric conditions i.e., temperature column operating at a rate of 6 0C min−1 from 80 to 3400 0C to synthesize palm oil and palm kernel polyol esters [22], [31], [32] by trans-esterifying oils with TMP. Acid-catalyzed and Base-catalyzed transesterification was discussed in the study led by Leelamani Pillai [12] via a chemical modification process known as Epoxidation [15], [20], [27], [28], [29], [30], in the development of bio-lubricants. Acids such as sulfonic, sulfuric, hydrochloric, and phosphoric acids [37] are most frequently used in acid-catalyzed transesterification, which is 4000 times slower than base-catalyzed reactions. High product yield and a sluggish rate of reaction. As a matter of fact, Vegetable oil transesterification is catalyzed by bases that move along more quickly. Most reactions are carried out with alkaline catalysts, including alkaline metal alkoxides and hydroxides as well as sodium or potassium carbonates [4], [8], [14], [15], [16], [17], [18], [19], [20], [23], [24], [34] due to their extremely high yield. The tribological performance of Vegetable oil-based bio-lubricants and Natural additives in lubrication via analysis of an array of physicochemical properties through spectral analysis viz., Fourier-transform infrared spectroscopy (FTIR) was confirmed by Nor Azmmi Masripan et al [13].

As a consequence of the mammoth utilization of fossil fuel, the diminution of crude or mineral oil reservoir stipulates the development of ecologically sound, sustainable alternative lubricants i.e., Bio-lubricants in order to protect the environment by plummeting pollution caused by the Petro -based lubricant. However, the proposed study aims to design and develop the replacement of petroleum i.e., non-renewable mineral oil-based lubricants through the manufacturing of biodegradable vis-à-vis renewable Bio-lubricant from non-edible plants i.e., castor [24], [25] as a sustainable substitute via an array of Chemical softening [7], [15], [16], [17], [18], [20], [27], [28], [29], [30], [33], [34], [36]. The chemical softening of castor oil has been reported to improve its oxidative stability [13], [17] and low-temperature properties. The hydroxyl value of the modified castor oil also increases, which can lead to a higher viscosity index [13], [5] and improved lubrication properties. In addition, the esterified castor oil has a higher flash point and pour point, which makes it more suitable for use in extreme temperature conditions. Although Vegetable oil-based Bio-lubricants are sustainable and ecologically viable still, they are not widely used because of several drawbacks including poor low-temperature performance and low thermal stability. Nevertheless, the paper addresses these drawbacks through the most prevailing research work that has been focused on chemical modification methods to make bio-lubricant, as a feasible alternative. The introduced initiative will be also pointed at decreasing pressure on the increasing demand for eatable oils and promising sustainability which the country was importing in large amounts from different countries of the world; ultimately farmers will be the first beneficiaries who are going to cultivate and harvest a farm of this plant as a raw material supplier [2], [35].