Currently, electromagnetic interference (EMI) pollution, which may seriously affect human health, are ubiquitous because of the popularization of smart and portable electronic gadgets (Zhan et al., 2021a, Zhan et al., 2018, Zhang and Gu, 2022). To protect against EMI pollution, EMI shielding nanocomposites with superhigh shielding effectiveness (SE) should be developed rapidly. Compared to metal materials, polymer composites are the best candidates in EMI shielding field because of their lightweight property and outstanding corrosion resistance (Zhan et al., 2023). Among the reported polymer composites with a high EMI shielding ability, waterborne polyurethane (WPU)–based EMI shielding composites have attracted many researchers’ attentions because they use water as the dispersion medium, reducing environmental contamination (Wang et al., 2019b, Xu et al., 2019, Zeng et al., 2016a). To date, some excellent WPU–based EMI shielding composites have been studied, such as anisotropic carbon nanotube (CNT)/WPU aerogels (Zeng et al., 2016a), four corners needle zinc oxide whiskers/silver/WPU films (Xu et al., 2019), reduced graphene oxide/WPU/cotton fabric (Wang et al., 2019b), and multilayer WPU conductive composites (Sheng et al., 2020). WPU materials derived from vegetable oils can be usually used as EMI shielding packaging for electronic equipment because of their low price and potential biodegradability (Man et al., 2019). As a noteworthy example, castor oil can function as a polyol in the WPU synthesis route and using this, Lu et al. (Lu et al., 2021) fabricated castor oil–based WPU/MXene films with a MXene content of 7 % and a thickness of 0.5 mm, whose SE reached 51.37 dB.

From a materials application perspective, antibacterial polymer composites with a good EMI shielding property have bright prospects and grand potential value in the market. To simultaneously enhance shielding and antibacterial abilities for polymer composites, it is common to introduce silver or MXene. For example, Gao et al. (2021a) reported a cotton nonwoven fabric coated with silver nanoparticles and polymer, which exhibited excellent SE (112 dB) and antibacterial ability. Liu et al. (2022a) found that the antibacterial efficiency of cellulose/MXene composite films with a SE value of 36 dB against Escherichia coli (E. coli) was as high as 97.62 %. However, the shortcomings of silver and MXene, such as high density, high price, and their easy oxidation, severely limit their applications in outdoor all-weather electrical equipment (Fan et al., 2020, Jia et al., 2021). CNTs, a one-dimensional form of carbon, possess excellent chemical and physical stability, outstanding electrical conductivity, and effective antibacterial properties. Therefore, CNTs can endow polymer composites with the dramatic electrical conductivity, resulting in outstanding EMI shielding property (Liu et al., 2022b). In our previous work, many excellent CNT/polymer–based EMI shielding composites have been reported, such as CNT/boron nitride/rubber nanocomposites (29.9 dB) (Zhan et al., 2020), self-healing CNT/acrylic copolymer foams (36.7 dB) (Zhan et al., 2021a), CNT/rubber foams (37.3 dB) (Zhan et al., 2019), and CNT/elastomer foams with low thermal conductivity (∼44 dB) (Xie et al., 2022a, Xie et al., 2022b). SE values of these above-mentioned composites are lower than the requirement of military products (>60 dB). Therefore, it is highly necessary to develop novel CNT/polymer-based EMI shielding materials with superhigh shielding ability. In addition, it’s hard to ignore the antibacterial capability of CNTs, attributed to their ability to disrupt cell membranes, cell morphology, and the metabolic processes of bacteria (Xin et al., 2019, Zhao et al., 2022). Saleemi et al. (2020) confirmed that antimicrobial activity of multi-walled CNTs was higher than that double-walled CNTs toward selected pathogens. Patil et al. (2023) found that introducing CNT@polydopamine improved the antimicrobial activities of polycaprolactone composites.

Besides their satisfactory shielding performance and antibacterial ability, CNTs can enable polymer composites to exhibit high thermal conductivity, which improves heat diffusion and is therefore beneficial for the lifespan of electronic components. CNT/boron nitride/rubber nanocomposites possessed a thermal conductivity up to 0.25 W/(m·K) (Zhan et al., 2020). The thermal conductivity of CNT/graphene/poly(butylene terephthalate)/poly(ethylene terephthalate) nanocomposites achieved 0.84 W/(m·K) (Gao et al., 2021b). Ecofriendly nanocomposites, comprising CNTs and vegetable oil–derived WPU, have potential applications in some fields, such as antibiotic materials, thermal conductors, and EMI shielding materials; however, reports investigating and supporting this have, as far as we know, not yet been published. This is ascribed to the formation of CNT aggregations in the WPU matrix coupled with their inferior manufacturability resulting from the high viscosity of the dispersion medium, particularly CNT/WPU composites with a high CNT content.

To disperse evenly CNTs, cetyltrimethylammonium bromide (CTAB), a popular surfactant, is often applied. Moreover, previous research has demonstrated that CTAB can annihilate bacteria by breaking the cell membranes and generating reactive oxygen species (Chen et al., 2014, Nakata et al., 2011). As a noteworthy example, Yu et al. indicated that CTAB imparted excellent antibacterial effects to montmorillonite (Yu et al., 2022). Therefore, it is herein hypothesized that combining CNTs and CTAB can be used to prepare antibacterial and thermally conductive WPU-based EMI shielding nanocomposites. The introduction of CTAB might improve the uniform distribution of CNTs in WPU matrix, facilitating an outstanding EMI shielding property as well as thermal conductivity.(Liu et al., 2020; Zhan et al., 2018) Furthermore, combining CNTs and CTAB can endow WPU nanocomposites with a high level of antibacterial activity.

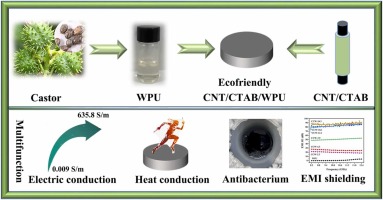

In this study, castor oil as a polyol was chosen to synthesize an ecofriendly WPU emulsion. Then, CNTs were homogeneously dispersed in the castor oil–based WPU matrix by a combination of ultrasonic-assisted solution mixing and a freeze-drying approach, assisted by the introduction of CTAB. Because of the high aspect ratio for CNTs coupling with their even distribution, the CNTs formed an interlinked network with each other. When the CNT content is 24.3 wt%, SE, electrical conductivity, and thermal conductivity for the prepared CNT/CTAB/WPU nanocomposites are 88.81 dB, 635.8 S/m, and 0.308 W/(m·K), respectively. Importantly, CNTs and CTAB endow the resultant composites with antibacterial activity against E. coli and Bacillus coagulans (B. coagulans). These composites have widespread applicability for reducing EMI pollution and accelerating thermal diffusion in materials as well as resisting the harm caused by bacteria.