Effect of extraction temperature and screw speed on oil extraction yield, extraction time and extraction time for Jatropha seeds

Table 2 shows the effect of extraction temperature (60, 80, 100 and 120 °C) and screw speed (60, 90 and 120 rpm) on oil extraction yield, extraction energy consumption and extraction time for Jatropha seeds. The results indicate that the oil yield increases with increasing extraction temperature and decreasing with increasing screw speed. It could be seen that the oil extraction yield significantly increased from 17.41 to 25.10 (by 30.64%), 15.74 to 23.51 (by 33.05%) and 11.85 to 20.66 (by 42.87%) % when the extraction temperature increased from 60 to 120 °C, respectively, at 60, 90 and 120 rpm. The results also indicate that the highest value of decreasing of oil extraction yield (25.10%) was found for 120 °C extraction temperature. This was may be due to that with higher temperatures, the extraction process of oil is easier treatment15.

The results indicate that the maximum Jatropha oil production is about 25.1% by the screw press at an engine speed of 60 rpm and preheating temperature of 120 °C. These results agreed with those obtained by Raja et al.28. This is due to the oil viscosity decreases with increasing extraction temperature, therefore, the oil exit from the cell easy. However, in these extraction conditions, much time is consumed with higher energy. The optimum yield of oil (23.51%) was obtained at temperatures in the range of 120 °C at speed of 90 rpm, the yield is slightly lower but the energy is much lower than are as will. Although the choice of these conditions reduced the production of the oil yield by 46.92%, but it saved in energy by a percentage of 37.93% and reduced the extraction time by 73.44% compared to the conditions of the highest oil production.

Multiple regression analysis was carried out to obtain a relationship between the oil yield as dependent variable and different both of extraction temperature and screw speed as independent variables. The best fit for this relationship is presented in the following equation:

$$ Y = 15.39 + 0.13T – 0.09S{\text{ R}}^{{2}} = 0.95 $$

(1)

where Y is the oil yield, %, T is the extraction temperature, °C, S is the screw speed, rpm.

This equation could be applied in the range of 60 to 120 °C of extraction temperature and from 60 to 120 rpm of screw speed.

Regarding, the effect of screw press conditions on extraction energy consumption for Jatropha seeds. The results indicate that the extraction energy consumption decreases with increasing screw temperature and screw speed. It could be seen that the extraction energy consumption significantly decreased from 12.00 to 10.50 (by 12.50%), 9.80 to 8.80 (by 10.20%) and 8.70 to 8.00 (by 8.05%) W.h when the screw temperature increased from 60 to 120 °C, respectively, at 60, 90 and 120 rpm. The results also indicate that the highest value of extraction energy (12.00 W.h) was found of 60 °C extraction temperature and 60 rpm screw speed. These results agreed with those obtained by Ibrahim et al.18 whose found lower extraction temperature and screw speed increase energy consumed. While, the energy consumed in extracting oil was as low as 8.0 W.h at 120 °C and 120 rpm, for extraction temperature and screw speed, respectively. These results are in agreement with those obtained by Ofori-Boateng et al.29.

Multiple regression analysis was carried out to obtain a relationship between the extraction energy consumption as dependent variable and different both of extraction temperature and screw speed as independent variables. The best fit for this relationship is presented in the following equation:-

$$ EC = 15.582 – 0.018T – 0.048S{\text{ R}}^{{2}} = 0.95 \, $$

(2)

where Y is the extraction energy consumption, W.h.

This equation could be applied in the range of 60 to 120 °C of extraction temperature and from 60 to 120 rpm of screw speed.

Considering the effect of screw press conditions on extraction time for Jatropha seeds, data obtained in Table 2 showed clearly that, the extraction time decreases with increasing screw temperature and screw speed. It could be seen that the extraction time significantly decreased from 3.70 to 3.00 (by 18.92%), 2.65 to 2.20 (by 16.98%) and 2.13 to 1.60 (by 24.88%) min when the screw temperature increased from 60 to 120 °C, respectively, at 60, 90 and 120 rpm. The results also indicate that the highest value of extraction time (3.7 min) was found of 60 °C extraction temperature and 60 rpm screw speed. These results agreed with those obtained by Ibrahim et al.18 whose found lower extraction temperature and screw speed increase extraction time. While, the lowest value of extraction time (1.6 min) was found of 120 °C extraction temperature and 120 rpm screw speed. These results agreed with those obtained by Ofori-Boateng et al.29.

Multiple regression analysis was carried out to obtain a relationship between the extraction time as dependent variable and different both of extraction temperature and screw speed as independent variables. The best fit for this relationship is presented in the following equation:-

$$ Et = 5.51 – 0.009T – 0.025S{\text{ R}}^{{2}} = 0.97 $$

(3)

where Et is the extraction time, min.

This equation could be applied in the range of 60 to 120 °C of extraction temperature and from 60 to 120 rpm of screw speed.

The results also indicate that the optimum condition of screw press for extracted Jatropha seeds were 120 °C extraction temperature and 90 rpm screw speed. It could be seen that the extraction oil yield, extraction energy consumption and extraction time were 23.51%, 8.8 W.h and 2.2 min, respectively.

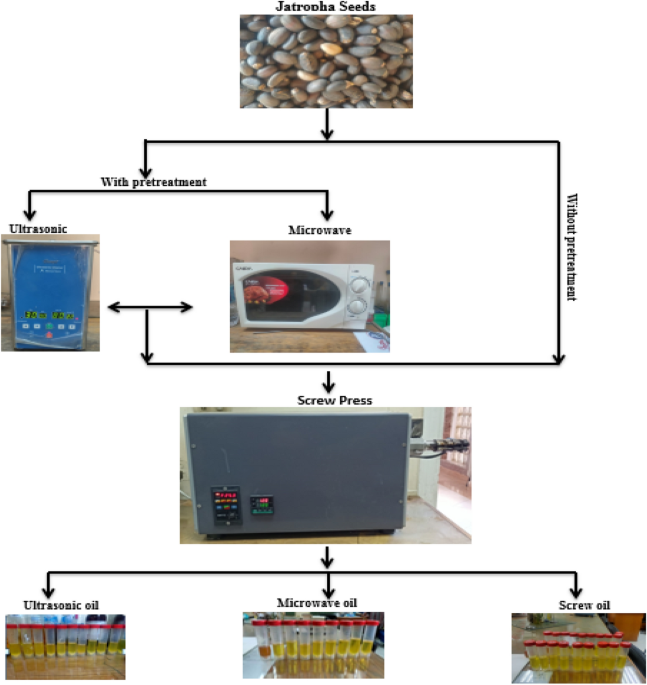

Pretreatment conditions

Effect of pretreatment conditions (microwave and ultrasonic) on oil extraction yield

Microwave treatment

Figure 3 shows the effect of microwave power levels (low, medium and high) and operating times (1, 3 and 5 min) on oil extraction yield from Jatropha seeds. The results indicate that the oil extraction yield decreases with increasing operating time for low, medium and high microwave power levels. It could be seen that the oil extraction yield significantly decreased from 25.63 to 22.84, 23.8 to 18.8 and 22.26 to 14.87% when the operating time increased from 1 to 5 min, respectively for low, medium and high microwave power levels. This is due to the high microwave power level causes evaporation of oil moisture from the cell, which leads to a decrease of oil yield. The results also indicate that the extraction oil at 120 °C extraction temperature recorded the highest value of oil extraction yield (25.63%) when adjusting on 1 min operating time for the low level of power of microwave treatment. The oil extraction yield was 23.51% at the same condition (120 °C extraction temperature and 90 rpm screw speed). These results are in agreement with those obtained by Khater et al.30.

Ultrasonic treatment

Figure 4 shows the effect of ultrasonic temperatures (40, 60 and 80 °C) and operating times (15, 30 and 45 min) on oil extraction yield from Jatropha seeds. The results indicate that the oil extraction yield were 20.96, 22.62 and 22.68, 22.04, 23.39 and 24.1and 24.8, 24.2 and 25.2% for 40, 60 and 80 °C ultrasonic temperatures, respectively at 15, 30 and 45 min operating time. The results indicate that the oil extraction yield increases with increasing ultrasonic temperature and operating time. It could be seen that the oil extraction yield significantly increased from 20.96 to 24.80, 22.62 to 24.20 and 22.68 to 25.20% when the ultrasonic temperature increased from 40 to 80 °C, respectively for 15, 30 and 45 min operating time. The results also indicate that the highest value of oil extraction yield (25.2%) was found of 45 min operating time and 80 °C ultrasonic temperature.

Finally, the results also indicate that the oil extraction yield from Jatropha seeds by using microwave pretreatment was lower than those of ultrasonic pretreatment for medium and high power levels and medium and high temperature, while the oil extraction yield from Jatropha by using microwave pretreatment was higher than those of ultrasonic pretreatment for low power levels and low temperature. It could be seen that the oil extraction yield were 24.157, 21.37 and 18.5% for low, medium and high microwave power levels, respectively, but they were 22.086, 23.18 and 24.73% for 40, 60 and 80 °C ultrasonic temperature, respectively. Also, the oil extraction yield form Jatropha seeds by using microwave pretreatment were higher than those of ultrasonic pretreatment for low operating time, while the oil extraction yield for extracted Jatropha seeds from Jatropha seeds by using microwave pretreatment was lower than those of ultrasonic pretreatment for medium and high operating time. It could be seen that the oil extraction yield were 23.897, 21.29 and 18.84% for 1, 3 and 5 min microwave operating time, respectively, but they were 22.6, 23.43 and 23.99% for 15, 30 and 45 min ultrasonic operating time, respectively.

Effect of pretreatment conditions (microwave and ultrasonic) on extraction energy consumption

Figure 5 shows the effect of microwave power levels (low, medium and high) and operating time (1, 3 and 5 min) on extraction energy consumption from Jatropha seeds. The results indicate that the extraction energy consumption for Jatropha seeds decreases with increasing microwave power level and operating time. It could be seen that the extraction energy consumption for Jatropha seeds decreased from 9.00 to 8.60, 8.70 to 8.30 and 8.55 to 8.10 W.h when the microwave power levels increased from low to high, respectively at 1, 3 and 5 min operating time. On the other hand, the energy consumed by microwave increases with increasing microwave power level and operating time. It could be seen that the energy consumed by microwave significantly increased from 3.0 to 16.0, 13.0 to 67.0 and 18.0 to 83.0 W.h when the operating time increased from 1 to 5 min, respectively for low, medium and high microwave power levels. The results also indicate that the highest value of extraction energy consumption for Jatropha seeds (9.0 W.h) was found of 1 min operating time and low microwave power level. While, the lowest value of extraction energy consumption for Jatropha seeds (8.1 W.h) was found of 5 min operating time and high microwave power level.

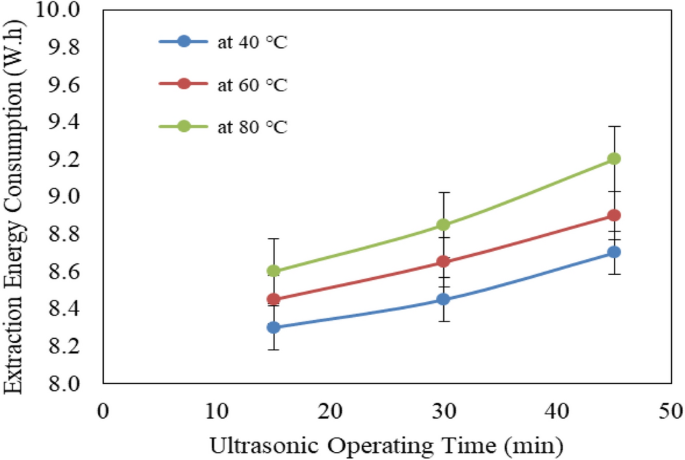

Figure 6 shows the effect of ultrasonic temperature (40, 60 and 80 °C) and operating time (15, 30 and 45 min) on extraction energy consumption from Jatropha seeds. The results indicate that the extraction energy consumption for Jatropha seeds increases with increasing ultrasonic temperature and operating time. It could be seen that the extraction energy consumption for Jatropha seeds significantly increased from 8.30 to 8.60, 8.45 to 8.85 and 8.70 to 9.20 W.h when the ultrasonic temperature increased from40 to 80 °C, respectively at 15, 30 and 45 min operating time. While, the energy consumed by ultrasonic increases with increasing ultrasonic temperature and operating time. It could be seen that the energy consumed by ultrasonic increased from 11.00 to 32.00, 15.00 to 34.00 and 18.00 to 38.00 W.h when the operating time increased from 15 to 45 min, respectively for 40, 60 and 80 °C ultrasonic temperature. The results also indicate that the highest value of extraction energy consumption for Jatropha seeds (9.20 W.h) was found of 45 min operating time and 80 °C ultrasonic temperature. While, the lowest value of extraction energy consumption for Jatropha seeds (8.30 W.h) was found of 15 min operating time and 40 °C ultrasonic temperature.

Finally, using MWAV treatments recorded lower values of energy consumption at medium and high level of power compared to ultrasonic treatments. Meanwhile, low level of microwave power recorded higher energy consumption compared to ultrasonic. It could be seen that the extraction energy consumption for Jatropha seeds were 8.75, 8.53 and 8.33 W.h for low, medium and high microwave power levels, respectively, but they were 8.48, 8.67 and 8.88 W.h for 40, 60 and 80 °C ultrasonic temperature, respectively. Also, the extraction energy consumption for Jatropha seeds by using microwave pretreatment was lower than those of ultrasonic pretreatment for medium and high operating time, while the extraction energy consumption by using microwave pretreatment was higher than those of ultrasonic pretreatment for low operating time. It could be seen that the extraction energy consumption were 8.8, 8.5 and 8.32 W.h for 1, 3 and 5 min microwave operating time, respectively, but they were 8.45, 8.65 and 8.933 W.h for 15, 30 and 45 min ultrasonic operating time, respectively.

Effect of pretreatment conditions (microwave and ultrasonic) on extraction time

Figure 7 shows the effect of microwave power levels (low, medium and high) and operating times (1, 3 and 5 min) on extraction time from Jatropha seeds. The results indicate that the extraction time for Jatropha seeds decreases with increasing microwave power level and operating time. It could be seen that the extraction time for Jatropha seeds significantly decreased from 2.18 to 2.017, 2.12 to 1.97 and 2.03 to 1.90 min when the operating time increased from 1 to 5 min, respectively for low, medium and high microwave power levels. The results also indicate that the highest value of extraction time (2.18 min) was found at 1 min operating time and low microwave power level. While, the lowest value of extraction time (1.90 min) was found at 5 min operating time and high microwave power level.

Figure 8 shows the effect of ultrasonic temperature (40, 60 and 80 °C) and operating time (15, 30 and 45 min) on extraction time from Jatropha seeds. The results indicate that the extraction time for Jatropha seeds increases with increasing ultrasonic temperature and operating time. It could be seen that the extraction time for Jatropha seeds significantly increased from 2.22 to 2.33, 2.27 to 2.42 and 2.32 to 2.50 min when the operating time increased from 15 to 45 min, respectively for 40, 60 and 80 °C ultrasonic temperature. The results also indicate that the highest value of extraction time (2.50 min) was found of 45 min operating time and 80 °C ultrasonic temperature. While, the lowest value of extraction time (2.22 min) was found of 15 min operating time and 40 °C ultrasonic temperature.

Chemical characteristics of Jatropha oil as affect by study treatments

Table 3 shows the effect of pretreatment (microwave and ultrasonic) of Jatropha seeds on the chemical analysis compared to without pretreatment on the same conditions (120 °C extraction temperature and 90 rpm screw speed). The results indicate that, using of microwave for pretreatment of Jatropha seeds was enhanced contents of oil yield properties more than those of ultrasonic pretreatment for Jatropha seeds and without pretreatment. On the other hand, using of ultrasonic for pretreatment of Jatropha seeds was enhanced quality of oil properties more than those of microwave pretreatment for Jatropha seeds and without pretreatment. It could be seen that the Palmitic acid, Stearic acid, Oleic acid, Linolenic acid and α Linolenic acid were 15.25, 17.61 and 15.92, 2.33, 1.86 and 1.07, 5.65, 5.82 and 5.13, 36.53, 35.22 and 36.35 and 40.24, 39.49 and 41.53% for non-treatment, microwave pretreatment and ultrasonic pretreatment, respectively. These results agreed with those obtained by Ogunniyi31 and Conceicao et al.32 whose found that the castor oil is presents in minor amount that includes Stearic acid (1%), Linoleic acid (4.2%), Linolenic acid (0.3%), Dihydroxystearic acid (0.7%),Oleic acid (3.0%), Palmitic acid (1%), and Eicosanoic acid (0.3%)15.

The results indicate that the acid values were 2.76, 3.34 and 2.88% for non-treatment, microwave pretreatment and ultrasonic pretreatment, respectively. Acid value is one of the important indicators of oil quality16. Omari et al.33 suggested that the high acid value of Jatropha oil may be due to the delay in seed extraction which influenced the lipase enzyme to hydrolyze the triglycerides into free fatty acid34.

Saponification number values were 191.7, 192.8 and 191.4 for non-treatment, microwave pretreatment and ultrasonic pretreatment, respectively. These results agreed with those obtained by Attia et al.3 and Yeboah et al.34. Also, the physicochemical properties of oil such as low acid value and free fatty acid percentage, high saponification value acid indicate that castor oil has good oil quality.

The molecular weight (MW) of oil value were 911.57, 910.18 and 912.00 for non-treatment, microwave pretreatment and ultrasonic pretreatment, respectively. The raw materials are converted into biodiesel through a chemical reaction involving alcohol and a catalyst. The specification of the molecular weight of crop oil is important for the biodiesel production process because the determination of the quantity of reactants is calculated according to the molecular weight of castor oil35. The results indicate that the lowest and the best of the molecular weight (MW) of oil value ultrasonic pretreatment then without pretreatment then microwave pretreatment.

Biodiesel production

The yield of biodiesel from 1 kg of oil was 0.916 kg. The efficiency of biodiesel production from Jatropha oil was 91.64%. The energy consumed from the magnetic stirrer and washing biodiesel by using boiler were 875 and 1177.5 W.h per kg oil, respectively. The total energy consumed to produce biodiesel from Jatropha oil was 2052.5 W.h per kg oil.

Physical and chemical properties of biodiesel produced from Jatropha oil

Table 4 shows the physical and chemical properties of biodiesel production from Jatropha oil compared to diesel oil. The results indicate that the density was 918.6 and 887.1 kg m–3 for Jatropha oil and Jatropha biodiesel, respectively, compared to 829 kg m–3 of diesel density. The kinematic viscosity was 34.33 and 5.69 m2 s–1 for Jatropha oil and Jatropha biodiesel, respectively, compared to 1.20 m2 s–1 of diesel kinematic viscosity. The dynamic viscosity was 6.73 and 3.25 mPa.s for Jatropha oil and Jatropha biodiesel, respectively, compared to 1.43 mPa.s of diesel dynamic viscosity. The flash point was 146 and 121 °C for Jatropha oil and Jatropha biodiesel, respectively, compared to 73.55 °C of diesel flash point.

The results also indicate that the heating value was 45,500 and 45,000 kJ kg–1 for Jatropha oil and Jatropha biodiesel, respectively, compared to 42,000 kJ kg–1 of diesel heating value. The cloud point was − 1 and 0 °C for Jatropha oil and Jatropha biodiesel, respectively, compared to − 6 °C of diesel cloud point. The cetane number was 39.12 and 73 for Jatropha oil and Jatropha biodiesel, respectively, compared to 41 of diesel cetane number. Cetane number indicates the tendency to knock. Cetane number is a measure of the combustion quality of a fuel in diesel engine and is related to the volatility of the fuel and ignition delay time. Ignition quality and cetane number affect engine performance, cold starting, warm up, and engine combustion roughness. The higher cetane number led to shorter ignition delay and engine performance reduction. Cetane number can be used without problems in fuel atomization and spray. Biodiesel burns with higher combustion efficiency. Cloud point demonstrates the biodiesel’s low-temperature operation. Long-chain saturated fatty acids have a significant impact on the cold flow characteristics of biodiesel. Biodiesel can be operated efficiently in cold conditions. Properties of biodiesel produced from Jatropha oil are compared with diesel. Better physical and chemical properties are for Jatropha biodiesel compared with diesel.