The concern with agro-industrial waste has increased considerably because of its incorrect disposal, which leads to several environmental problems as groundwater pollution, odor emission, crowded landfills, and the production of uncontrolled greenhouse gases (Calabrò et al., 2016). So, novel approaches for the destination of agro-industrial waste have been stimulating in scientific research. The nourishment industry is the main sector that produces a high amount of waste (El Gheriany et al., 2020; Kazemi et al., 2019; Ramlee et al., 2019). According to the Food and Agriculture Organization of the United Nations, Brazil produced 1,3 billion tons of agriculture waste annually, which 1/3 of the food intended for consumption being wasted due to the absence of viable recycling strategies (Costa Filho et al., 2017). On the other hand, the valorization of agro-industrial waste is sustainable, economical, inexpensive, rich in organic materials, and it is an abundant resource. So, it could be considered as one of the most efficient alternatives to recycle, and consequently for the production of high added-value products (Kazemi et al., 2019).

Currently, strict legislative policies encourage many industries to adopt new strategies that replace non-renewable resources with more sustainable and renewable sources. For example, the use of agro-industrial solid waste has been called “biomass economy,” which is the conversion of lignocellulosic waste into bioenergy and new chemicals (Väisänen et al., 2016). Also, one condition for sustainable agriculture is the efficient recirculation of nutrients from biomass, e.g., algae-bacteria systems that represent a strategy for nutrient recycling and of the removal of contaminants in wastewater related to biological reactions and symbiotic mechanisms that produce potential sustainable energy sources such as biodiesel, fertilizers, and biogas (Sepehri et al., 2020). However, the higher price of nutrients for the cultivation of algae-bacteria induces coupling energy production with agro-waste resources (Sepehri and Sarrafzadeh, 2019). Therefore, the destination of these residues is limited to the linear industry, but it is unlimited from the point of view of the circular economy due to the possibilities of bioenergy and a large amount of products with high added value that can generates from agro-waste.

Among the existing food residues, açaí seed is lignocellulosic biomass with no added value for the food industry, as only 10–20% of the pulp is used for consumption. Açaí berry is a species of palm trees found in the north area of Brazil, and it is native to the Amazon region. According to IBGE (2018), the major production was 66% in the state of Pará. Regarding Brazil production, approximately 221 kt of açaí fruit was produced in 2018 (IBGE, 2018; Souza et al., 2020), which 198.9 kt is considered a waste of this industry. The core of the fruit is the main residue of açaí fruit. It is an oleaginous seed, formed by a small solid endosperm attached to a tegument, which at maturity is rich in cellulose, hemicellulose, and lignin (Emely et al., 2019). Currently, açaí seed has been used to various applications such as charcoal production for methylene blue sorption (Emely et al., 2019), antioxidants for the treatment of carcinoma cells (Gordon et al., 2012; Martinez et al., 2018), and other biomedical applications, biochar as a soil conditioner (Keisuke et al., 2020), enrichment of residual yeasts (Saccharomyces cerevisiae), and production of nanoporous carbon for CO2 capture (Souza et al., 2020). Some researchers have found that açaí seed has a high antioxidant capacity, protective against cancer due to phenolic compounds, mainly flavonoids (Martinez et al., 2018; Rossetto et al., 2020). Hence, there is a bioeconomic interest to aggregate new values to these residues, aiming to prevent the accumulation or the incorrect disposal, adding value to the productive chain, and improving local and social development (Monteiro et al., 2019; Rossetto et al., 2020).

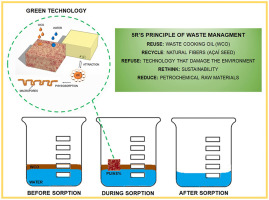

Due to exponential population growth, there has been an increase in demand and incorrect disposal of cooking oil (WCO) from frying activities in the food industry, restaurants, hotels, and homes, causing environmental problems due to pollution of land and water resources drinking water (Uz and Gökalp, 2020). One of the significant environmental issues that arise is the eutrophication process promoting by a thin layer of oil dispersed in rivers and water resources, which blocks the pass out of sunlight through the river, disturbing the oxygen supply for aquatic biota (Azahar et al., 2016). Besides, WCO is composed of free fatty acids that generate lousy odor and cause metal and concrete corrosion (Tsai, 2019). Regarding the adsorption and purification of WCO, which contains a large amount of water and free fatty acids (FFA), previous studies reported WCO adsorption methodologies such as adsorbents based on activated carbon, clay minerals, and natural fibers. However, there is a lack of studies related to WCO adsorption with polyurethane foams (Buczek and Chwiakowski, 2008; Putra et al., 2014; Sulyman et al., 2018). Since WCO reuse cooperates with reverse logistics, it has been applied for biodiesel, stearic acid, methyl ester, and soap feedstocks. This way, combining two residues, biomass waste, and waste cooking oil, proves the possibility of minimizing non-renewable resources to create new materials. Thus, that promotes clean water and sanitation, sustainable cities and communities, responsible consumption and production, life on earth, and human health. So, it is a great interest for environmental and economic technologies and contributes to fulfilling the 17 Sustainable Development Goals developed by the United Nations (ONU).

The use of biocomposites for the removal of oils by an adsorption/absorption process can be a solution to two environmental problems, i.e., it helps rid the environment of oil spills, and it helps in the reduction of solid waste accumulation (Mahmoud, 2020; Wang and Deng, 2019). Polyurethane foams are considered highly efficient for fast oil sorption due to their porous, hydrophobic, and oleophilic characteristics (Amorim et al., 2020). Besides, açaí waste has low cost, low density, biodegradability, which contributes to its economic recovery (Mahmoud, 2020; Tayeb et al., 2020). These biocomposites may be desirable for organizations, industries, and society from an economic and environmental point of view because they have applications and characteristics which make them sustainable, e.g., production of improved insulation materials to reduce energy consumption, heat pipe insulation and sound, raw materials with an improved carbon footprint and reduced odors and emissions in internal applications (Eling et al., 2020). Polyurethane foam has recently been studied as packing materials in chemical scrubbers to treat prevalent gas pollutants in sewage and wastewater treatment plants and as supports in biotrickling filters and bio-scrubbers for gas treatment systems (Nisola et al., 2018).

Thus, this work proposes an alternative for açaí seed residue as a filler in castor oil-based polyurethane, and future applications as oil/water separating filter in grease boxes in homes, restaurants, institutional and industrial fields as an alternative for biodiesel, chemicals, and soap obtaining from the recycled cooking oil.