Polymers play an essential role in the 21st century, shaping modern life. Polyurethane (PU) is a crucial multifunctional polymer material, which is mainly prepared from polyols and polyisocyanates (Aguirresarobe et al., 2021, Kang et al., 2018, Peyrton and Avérous, 2021, Zeng et al., 2023). Currently, PU has been applied in numerous industries, such as paint, biomedicine, footwear materials, foams, adhesives, and so on. According to the latest report, the market transaction amount of PU reached $70 billion in 2020. It is anticipated that by 2028, the size of polyurethane materials in the global market will reach 73 billion USD (Mouren and Avérous, 2023, Shi et al., 2020). However, the preparation and application process of traditional solvent-based PU result in a significant amount of emissions of VOCs and HAPs, which have adverse effects on both environmental pollution and human health. Therefore, waterborne polyurethane (WPU) has gradually begun to replace solvent-based PU with the improvement of environmental protection legislation (Lyu et al., 2022, Sternberg and Pilla, 2023).

Nowadays, the government is focusing on green and sustainable development, in recent years, the use of bio-based raw materials (such as vegetable oils and their derivatives, cellulose, curcumin, lignin, isosorbide, etc.) has become a popular trend to effectively replace petroleum-based raw materials. (Li et al., 2023, Salzano de Luna, 2022, Shen et al.,2023). Among the aforementioned materials, vegetable oils, and derivatives are considered one of the most promising polyols due to their low prices, minimal toxicity, and renewability. So far, it is reported that several bio-based WPU systems have already been developed using renewable resources. For example, Zhang et al. successfully synthesized a series of novel vegetable oil-based cationic WPU using castor oil and amino acids as the main raw materials (Liang, et al., 2021). Guo’s team chemically modified lignin via thiol-ene chemistry and utilized lignin-based polyols to synthesize lignin-based polyurethane (LPU) coatings, which demonstrated excellent corrosion resistance (Cao, et al., 2020). In addition, Wang et al. prepared a divalent alcohol (OPG) and employed it to synthesize bio-based WPU, demonstrating enhanced mechanical properties (Wang, et al., 2022). Castor oil is a triglyceride that contains numerous reactive sites, it can be used as a precursor to prepare high-performing WPU in the case of no reprocessing. Therefore, castor oil has the potential to be a promising polyol (Zhang, et al., 2017). However, the flexible chain and the relatively low amount of OH limit the overall performance of WPU, particularly its mechanical properties (Liang et al., 2018). Currently, researchers are interested in increasing the Tg values of WPU to enhance its mechanical performance through various methods, including controlling content between soft and hard segments, increasing the degree of cross-linking density, improving intermolecular forces, and adding nano-fillers (Gogoi and Karak, 2022, Wang et al., 2020, Wang et al., 2019, Xie et al., 2022, Zhang et al., 2021). For instance, Tang et al.’s research group introduced isosorbide and L-tyrosine derived from cyclic dipeptides, which were used in the WPU systems, respectively. The ratio between them and castor oil was subsequently adjusted to prepare a series of bio-based WPU. The findings demonstrated that the latter exhibited superior mechanical performance and corrosion resistance. (Shen et al., 2022). Zhang et al. discovered that by partially substituting glycerol with castor oil, the overall performance of castor oil-based WPU could be significantly enhanced (Zhang et al., 2021). The study mentioned above presented a wide range of ideas for sustainable resources as alternatives to traditional fossil-based resources. Despite extensive efforts in molecular design and functional modification by researchers, the mechanical performance of castor oil-based WPU has not been satisfactory so far. Additionally, the complex preparation process significantly limits its practical application performance and increases the difficulty of actual production. Hence, it is still imperative to exploit cost-effectively, simple, and feasible preparation techniques to synthesize high-performance bio-based WPU.

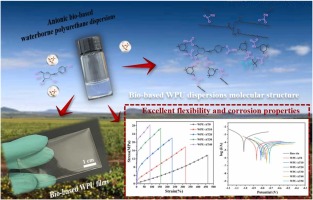

The compound arbutin (AT), a naturally occurring substance found in various plants, exhibits biological activity and possesses immense potential for applications in the fields of biomedicine and cosmetics (Saeedi et al., 2021). Zhu et al. summarized the current research progress in the preparation of AT, mainly including the utilization of enzymatic and microbial methods (Zhu et al., 2018). Park et al. reported a new method for preparing gold nanoparticles (GNPs) using AT as one of the bioactive components due to its strong reducing power. The resulting arbutin/GNPs complex exhibited excellent anti-inflammatory and whitening properties, offering a novel strategy in the field of cosmetics that incorporates Chinese herbal and botanical ingredients (Park et al., 2019). In this work, arbutin (AT) was a renewable polyol that can be directly applied to design the structure of castor oil-based WPU networks. Interestingly, the molecular structure of AT brought numerous performance advantages. First, aromatic building blocks provided unique polymer properties such as rigidity, heat resistance, and barrier performance. The polyhydroxy groups of molecular structure played a vital role in cross-linking. The unique molecular structure of AT could provide a multitude of hydrogen bond-binding sites in particular. It was constructed using castor oil and AT as polyols to prepare a suite of bio-based WPUs. The properties were systematically characterized to evaluate the impact of AT content. Moreover, the corrosion resistance of WPU coating on Q235# iron was also discussed. This work aimed to explore a novel high-performance WPU coating with excellent anti-corrosion properties combined with preeminent mechanical performance and provide an effective approach.